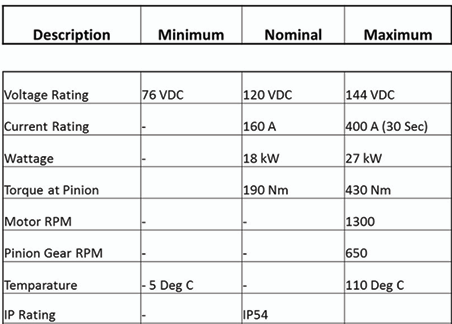

Each Locomo on 22 Drive System consists of the following components:

1. AC Driven Permanent Magnet High Torque Motor.

2. 400 Amp 120VDC Digital Motor Controller.

3. Microcontroller Can Bus Interface Module.

4. Optional Emergency/Park Braking System.

5. Mechanical Brake Override.

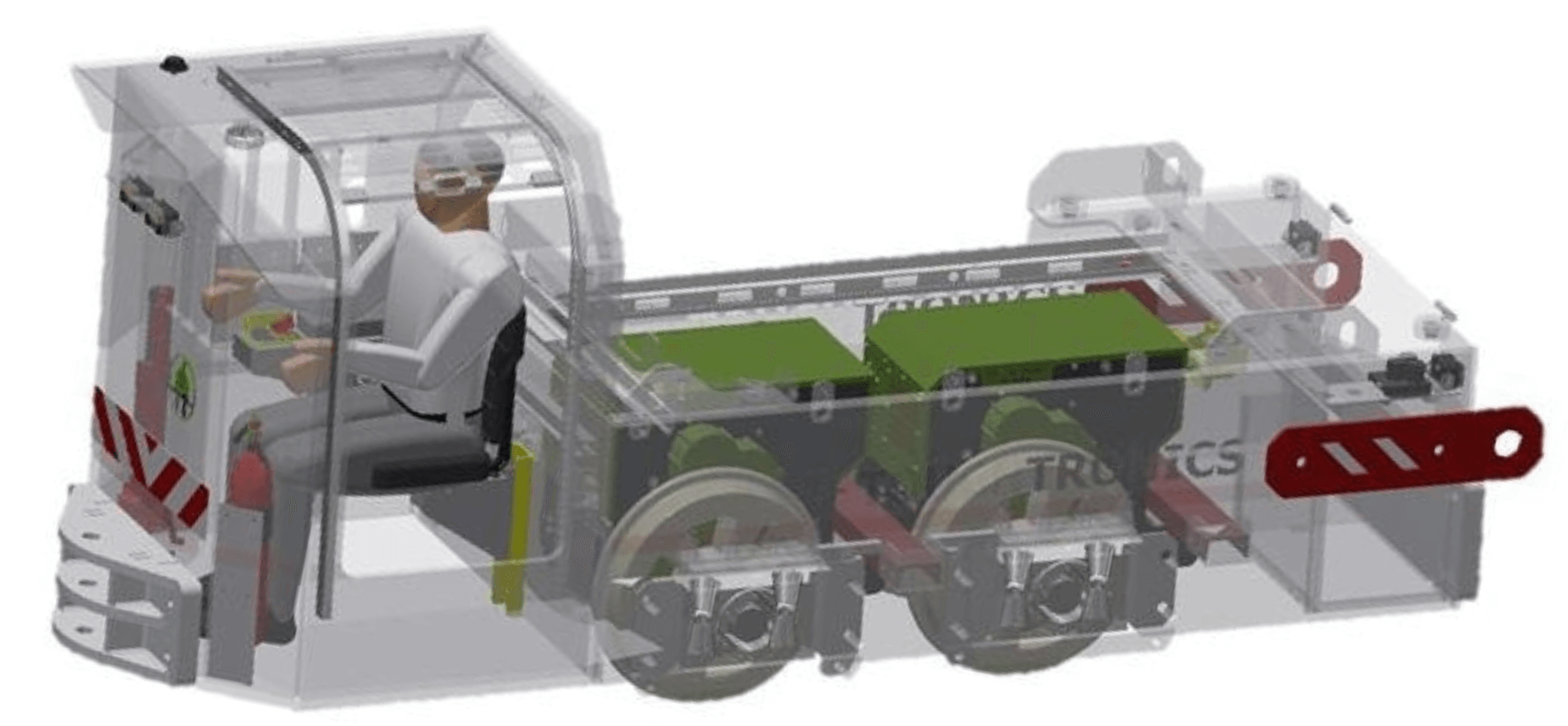

• Modular internal components for easy removal

• Motor can be removed from housing without removing wheel set from locomotive

• Simplified brake pad replacement

• Full motor system diagnostic information available on connected LMS system

• Motors work independently (Dual redundancy)

• Motors are speed controlled and not power controlled, reducing wheel slip (Improved safety)

• Motors have Improved efficiency compared to brushed DC motors.

• Regenera ve Braking, charges ba ery during braking (Improved efficiency)

• Built in fail safe spring applied caliper brake per motor (Dual redundancy/improved safety)

• Separate internal controller per motor (Dual redundancy)

• Short inductance loops due to controller close to motor (Improved reliability)

• Majority of wiring internal to motor housing. Only Power and DCU cables connect externally to

motor housing (Improved reliability)

• Motor replaceable without removing motor housing from locomotive (Shorter down me)

• Designed for 12-ton locomotive (Future progression)

• CAN based control system, this provides the mechanism to remotely control the locomotive

• Cost effective design

Sales

Our sales team can assist with your needs

- Wynand Mulder 082 8211 910

- Vincent Mulder 079 5174 489

- Byron Smith 082 3959 900