• Cost saving – low maintenance

• Top works protected for robust applications

• Double flanged

• Supporting seal fitted to gland seal for longer life on gland seal

• Valves do not need to be removed from the line as the gland seal allows for adjustment and replacement while in the line.

• All resilient seal linings offer ‘no’ leakage on gas, powders and liquids.

• Our design offers positive seating at all times preventing ‘cavity’ on the bottom where solids accumulate

• The self-cleaning section prevents slurry or solid build up that allows free movement of the blade at all times

• Depressurise the circuit and place the valve in closed position

• Rising stem valves. Release the spindle or stem from the gate

• Loosen the screws of the yoke and remove it

• Loosen the nuts of the gland follower and remove it

• Remove the old packing rings and clean the stuffing box

• Insert the new packing rings making sure that the ring joints alternate

• Once the necessary packing rings have been inserted, proceed with a steady initial tightening of the gland follower

• Fix the stem to the gate

• Remount the gate guards

• Carry out some operations with a loaded circuit and then retighten the gland follower to prevent leakage

Body: Cast Iron, Carbon Steel, Stainless Steel:

Blade: Stainless Steel 304/314, Rocklast Hardened Material

Hand Wheel: Cast Iron

Lining: Natural Rubber, EP DM, Polyurethane

Gland: Cast Steel

Pillar: Cast Steel

Spindle: 304 Stainless Steel

Rev Nut: Bronze Lg2

Lubrication:

Recommendation – twice yearly. Remove protection cap, fill stem protector cap halfway with calcium-based grease.

Grease Characteristics:

High water resistant, low ash content and excellent adherence.

Storage:

Store in well-ventilated room. Valves should not be exposed to temperatures higher than 300 ºC. If stored outside, cover valve and protect from heat and direct sunlight.

Information Required to Quote:

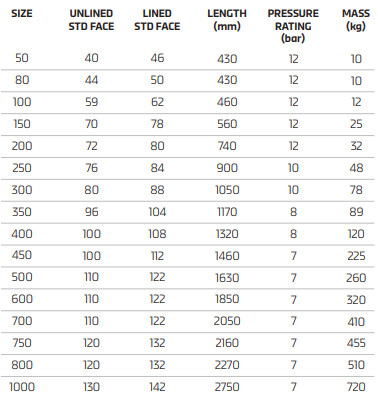

• Size of Bore

• Working Pressure

• Temperature

• Table Drilling

• Operation (Handwheel, Gearbox or Actuator) Media (Chemical, slurry etc.)

Sales

Our sales team can assist with your needs

- Wynand Mulder 082 8211 910

- Vincent Mulder 079 5174 489

- Byron Smith 082 3959 900