html slideshow by WOWSlider.com v7.7

WM Diaphragm Valve

Rolling Stone Idler

Valves

Locomotives

Pumps

We specialize in the manufacturing, repairing and designing valves, locomotives and mining equipment.

Tel: 011 412 4536

Cell: 082 821 1910

Email: info@minetrack.co.za

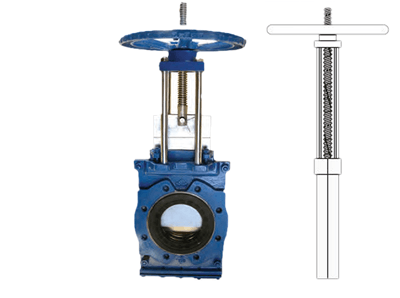

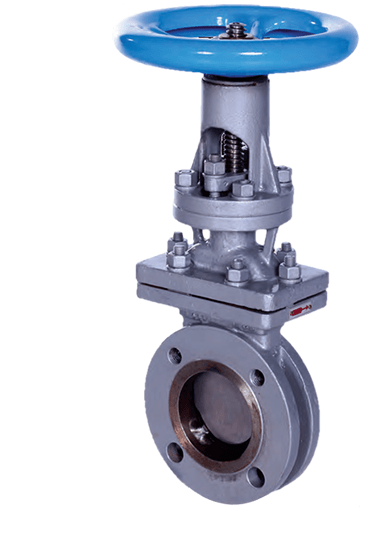

TAP VALVE MANUFACTURERS VALVES have been designed for higher pressures.

Size |

Unlined |

Lined |

Length |

Pressure Rat ing |

Mass |

| 50 | 40 | 46 | 430 | 12 | 10 |

| 80 | 44 | 50 | 430 | 12 | 10 |

| 100 | 59 | 62 | 460 | 12 | 12 |

| 150 | 70 | 78 | 560 | 12 | 25 |

| 200 | 72 | 80 | 740 | 12 | 32 |

| 250 | 76 | 84 | 900 | 10 | 48 |

| 300 | 80 | 88 | 1050 | 10 | 78 |

| 350 | 96 | 104 | 1170 | 8 | 89 |

| 400 | 100 | 108 | 1320 | 8 | 120 |

| 450 | 100 | 112 | 1460 | 7 | 225 |

| 500 | 110 | 122 | 1630 | 7 | 260 |

| 600 | 110 | 122 | 1850 | 7 | 320 |

| 700 | 110 | 122 | 2050 | 7 | 410 |

| 750 | 120 | 132 | 2160 | 7 | 455 |

| 800 | 120 | 132 | 2270 | 7 | 510 |

| 1000 | 130 | 142 | 2750 | 7 | 720 |

| Body | Cast Iron • Carbon Steel • Stainless Steel |

| Blade | Stainless Steel 304/314 |

| Rocklast Hardened Material | |

| Hand Wheel | Cast Iron |

| Lining | Natural Rubber • EP DM • Polyurethane |

| Gland | Cast Steel |

| Pillar | Cast Steel |

| Spindle | 304 Stainless Steel |

| Rev Nut | Bronze Lg2 |

| Lubrication | Recommendation - twice yearly. |

| Remove protection cap, fill stem protector cap half way with calcium based grease. |

|

| Grease Characteristics | High water resistant, low ash content and excellent adherence. |

| Storage | Store in well ventilated room. |

| Valves should not be exposed to temperatures higher than 300 C. | |

| If stored outside, cover valve and protect from heat and direct sunlight. |

Size of Bore • Working pressure • Temperature • Table drilling • Operation (Handwheel, Gearbox or Actuator) Media (Chemical, slurry etc.)