WM Diaphragm Valve

Rolling Stone Idler

Valves

Locomotives

Pumps

We specialize in the manufacturing, repairing and designing valves, locomotives and mining equipment.

Tel: 011 412 4536

Cell: 082 821 1910

Email: info@minetrack.co.za

Sizes: 50mm - 250mm

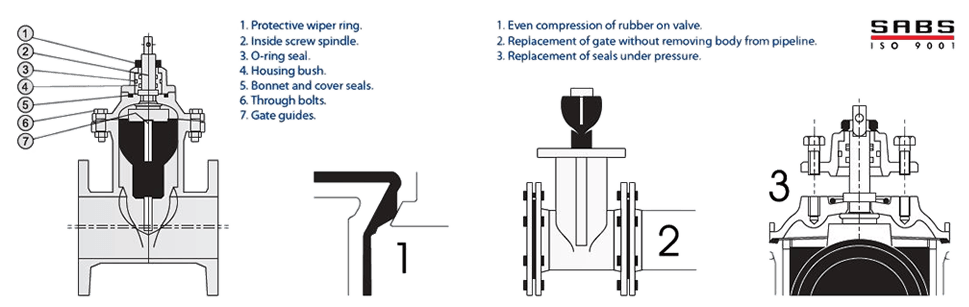

The Right 16 resilient seal gate valve is the most widely used of its type for water reticulation service in Europe. It conforms dimensionally to SABS 664 Class 16. The resilient seal gate valve is called for in 90 percent of waterworks applications in Europe. The reason for this can be seen in the features illustrated in the following pages.

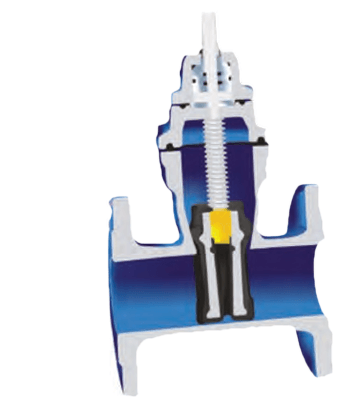

Seating: Uniform contact between body and gate at every point ensures even compression of the rubber, guaranteeing a complete seal. The profile of the sealing surfaces is designed to eliminate wear on the seat faces as the gate closes. The sealing angle is constant and there is no sliding contact between faces in contact, eliminating any shearing, tearing or wearing of the rubber seal. The resilient seal accommodates body distortion resulting from pressure or pipe stresses, and offers drop-tight seal over the whole range of pressures.

Maintenance: Gland repacking is eliminated by the use of the nylon seal bush supporting spindle seal O-rings. With the valve in the ‘Full-Open’ position, a positive back seal is effected, enabling the spindle seals to be replaced with the valve under pressure. The bonnet is secured to the cover by two set screws and the whole assembly can be replaced within two minutes. Valve gates can be replaced without removing the body from the pipeline. All gates of the same size are interchangeable without ‘matching’.

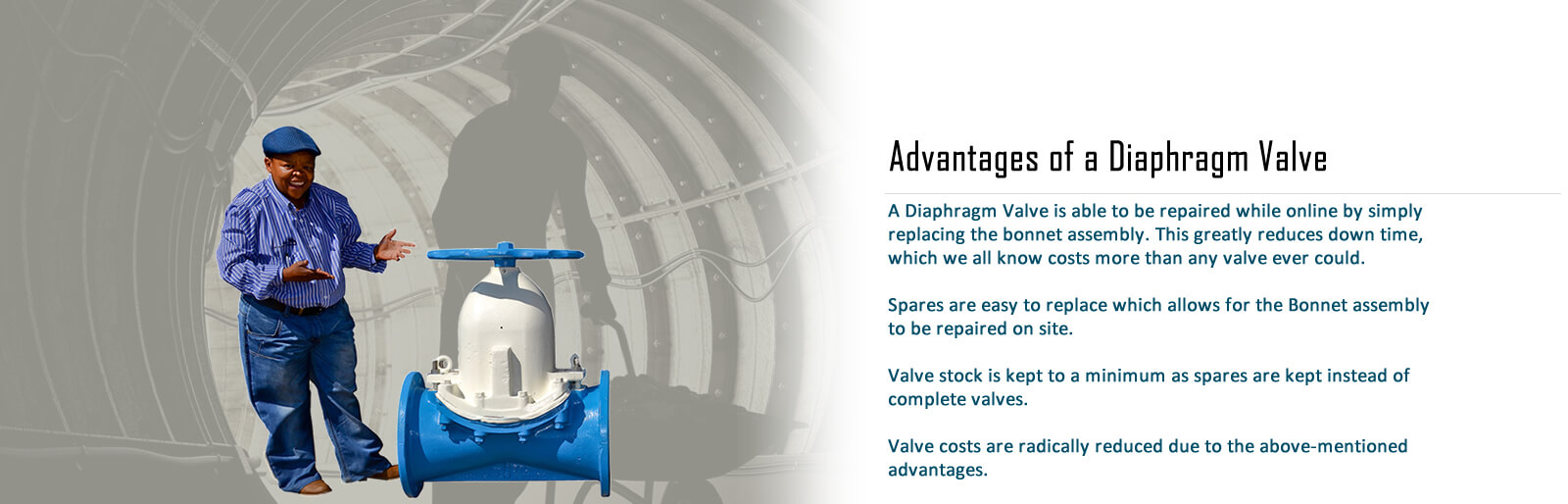

Advantages

Positive shut-off: Positive tight shut-off over the whole range of pressures.

Reduced operational torque: Low gland friction reduces operating torque.

The polished stainless steel spindle is supported in the nylon housing bush

and sealed by two O-rings. By eliminating the conventional stuffing box the

spindle torque is reduced by 30 percent.

Convenient installation: The gate is positively guided by gate tongues

located in grooves in the body which, together with the nylon bush guiding

the spindle in the upper housing, permits installation of the valve in vertical,

horizontal and inclined piping.

No reduction gearing needed: Due to the low sealing and gland friction

torque, all valves in this series can be operated against a full differential

pressure of 1/6MPa without the use of reduction gearing.

No pockets: The smooth straight-through body passage reduces head loss to

little more than that of a straight pipe of the same length and diameter. There

are no recesses in the body where solids can lodge, and gate sealing flanges

are unaffected by solids in suspension.

Interchange ability: Supplied to

SABS 664 dimensions, the valves

are completely interchangeable

in the pipeline with wedge gate

valves of the same size. Flanged,

spigot and socket end body

configurations permit use of

the valve with steel, asbestoscement

and uPVC piping.

Minimal maintenance:

The valve gate and spindle seal

assembly can be changed in

less than five minutes without

removing the valve from the pipeline.

Chemical resistant: The stainless steel spindle is impervious to chemical

attack from chemicals used in water treatment.

Lining: Simple, clean lines of the internal body configuration.

Manual Operation

The table below indicates the differential pressure in kPa against which Right

valves can be closed using standard mechanisms. The figures are based on

the application by one man exerting an effort of 200 Newton’s simultaneously

with each hand on the rim of a standard hand wheel. In all cases spindle

threads are single-start 12.7mm pitch. For waterworks service, Right valves

can be operated up to the full differential pressure of 1.6MPa using a standard

Tee key without reduction gearing.

DIFFERENTIAL kPa |

|||||||

Valve Size |

50 | 80 | 100 | 150 | 200 | 250 | 300 |

| 1600 | 1600 | 1600 | 1520 | 750 | 585 | 585 | |

Electric Operation

The table below indicates the torque required in Newton meters to overcome

the full differential pressure of 1.6MPa across the valve.

TORQUE N.m |

|||||||

Valve Size |

50 | 80 | 100 | 150 | 200 | 250 | 300 |

| 50 | 50 | 60 | 80 | 200 | 250 | 300 | |